The Significance Of Mineral Chemical Properties In Industrial Applications

In the world of industrial applications, the significance of mineral chemical properties cannot be understated. These properties play a crucial role in determining the suitability of minerals for various industrial processes and applications. From their composition and stability to their reactivity and conductivity, the chemical properties of minerals provide valuable insights that help industries make informed decisions. Understanding these properties allows for the development of more efficient and effective industrial processes, ultimately leading to advancements in a wide range of industries, including manufacturing, energy, and construction. In this article, we will explore the importance of mineral chemical properties in industrial applications and delve into their implications for various sectors.

Introduction

In the world of industrial applications, minerals play a crucial role. Their composition and chemical properties determine their suitability for various industrial processes and products. Understanding these properties is essential for maximizing their use and ensuring high-quality results. This article will delve into the composition of minerals, their chemical properties, and their applications in different industries.

Composition of Minerals

Types of Minerals

Minerals are naturally occurring inorganic substances that are formed through geological processes. They can be classified into several categories based on their chemical composition and crystal structure. Common types of minerals include silicates, carbonates, sulfides, oxides, and halides. Each type has its unique characteristics, making it suitable for specific applications in various industries.

Chemical Elements in Minerals

Minerals are composed of different chemical elements, which contribute to their distinctive properties. Elements like aluminum, iron, calcium, potassium, and sodium are frequently found in minerals. These elements give minerals their physical and chemical attributes, such as hardness, color, density, and reactivity. The presence of specific elements in minerals determines their suitability for particular industrial processes.

Chemical Properties of Minerals

Reactivity

The reactivity of minerals refers to their ability to undergo chemical reactions. This property is crucial in industrial applications where minerals interact with other substances to produce desired outcomes. Some minerals exhibit high reactivity, making them useful as catalysts or as raw materials in chemical synthesis. For example, platinum and palladium are highly reactive minerals used as catalysts in the petroleum industry.

Solubility

Solubility refers to the ability of minerals to dissolve in various solvents, such as water or acid. Some minerals are highly soluble, while others are insoluble or only slightly soluble. Solubility plays a significant role in industries like pharmaceuticals, where minerals are used to create soluble salts or as carriers for drug formulations. Having knowledge of a mineral’s solubility allows industries to optimize their processes and formulations.

Acidity and Alkalinity

The acidity or alkalinity of minerals is determined by their pH value. Acidic minerals have a pH value less than 7, while alkaline minerals have a pH value greater than 7. This property is essential in industries where the pH of a solution needs to be controlled. For instance, in chemical manufacturing, minerals with specific acidity or alkalinity are used to adjust the pH of reactions, ensuring optimal conditions for desired chemical transformations.

Industrial Applications of Minerals

Minerals find applications in various industries due to their diverse chemical properties. Let’s explore some of the key areas where minerals play a significant role.

Minerals for Building Materials

Cement Production

One of the most essential minerals in cement production is limestone, which primarily consists of calcium carbonate. When heated, limestone decomposes to form calcium oxide, which reacts with water to produce calcium hydroxide. This process, known as hydration, leads to the hardening of cement. Other minerals, such as silica, alumina, and iron oxide, are also added to cement to provide specific properties like strength, stability, and color.

Brick Manufacturing

Clay minerals, such as kaolinite and illite, are crucial in brick manufacturing. These minerals have excellent plasticity, allowing them to be easily molded into the desired shape. When fired at high temperatures, clay minerals undergo a chemical transformation known as vitrification, forming a solid and durable brick. Other minerals, like feldspar, are added to clay to improve the strength and appearance of the final product.

Minerals for Energy Production

Coal Combustion

Coal, a fossil fuel, is primarily composed of carbon and various mineral impurities. When coal is burned for energy production, these minerals can have significant effects on the combustion process. Minerals like sulfur and mercury can be released into the atmosphere, contributing to air pollution. Therefore, understanding the mineral composition of coal and implementing proper emission control technologies is vital to minimize environmental impacts.

Natural Gas Processing

In natural gas processing, minerals such as silica and alumina play a vital role in removing impurities from the gas stream. These minerals are used as adsorbents in processes like dehydration and sweetening, where they selectively remove water and other contaminants. The efficiency and effectiveness of these processes depend on the chemical properties and surface characteristics of the minerals used.

Minerals for Metallurgical Processes

Iron and Steel Production

Iron ore, a mineral rich in iron oxides, is a crucial raw material for steel production. The chemical properties of iron ore, such as its iron content and impurities, determine its suitability for different steelmaking processes. For example, iron ore with high iron content is preferred in blast furnace operations, while iron ore with lower iron content is suitable for direct reduction processes.

Aluminum Smelting

Bauxite, a sedimentary rock containing aluminum minerals, is the primary source for aluminum production. The chemical composition of bauxite, particularly its alumina content, influences the efficiency of the aluminum smelting process. To extract aluminum, bauxite is first refined to produce alumina, which is further processed through electrolysis to obtain pure aluminum metal. The chemical properties of bauxite impact the energy consumption and overall cost of aluminum production.

Minerals in Chemical Manufacturing

Fertilizer Production

Minerals like phosphate rock and potash are essential in fertilizer production. Phosphate rock contains phosphorus, a vital nutrient for plant growth, while potash provides potassium. These minerals are processed to produce fertilizers that replenish the soil’s nutrient content and improve crop productivity. Understanding the mineral composition and chemical properties ensures the production of high-quality fertilizers tailored to specific soil and crop requirements.

Polymer Synthesis

Minerals, such as clays and zeolites, are used as catalysts or additives in polymer synthesis. They can influence the polymerization process, leading to desired properties like molecular weight, polymer structure, and thermal stability. Different minerals offer varying catalytic activities and selectivities, allowing industries to produce a wide range of polymers for diverse applications.

Minerals in the Pharmaceutical Industry

Medicine Formulation

Minerals find applications in pharmaceutical formulations as excipients or inactive ingredients. They can enhance the stability, solubility, and bioavailability of active pharmaceutical ingredients (APIs). Minerals like calcium carbonate and magnesium stearate are commonly used as fillers or lubricants in tablet formulations, ensuring the proper release and absorption of APIs in the body.

Active Ingredient Extraction

Certain minerals are utilized in the extraction of active ingredients from natural sources. For example, activated carbon, a mineral-based adsorbent, is commonly used to purify medicinal plant extracts by adsorbing impurities. Additionally, mineral-based catalysts can be employed in chemical reactions or enzymatic processes to extract and isolate active compounds efficiently.

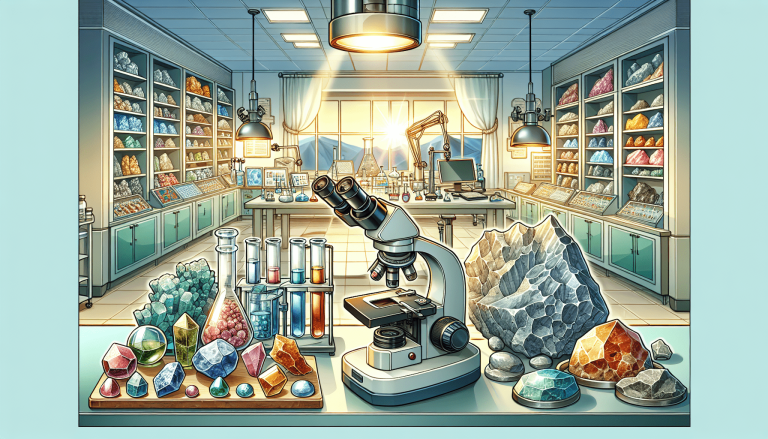

Quality Control and Testing

Chemical Analysis Techniques

Quality control of minerals involves analyzing their chemical composition and physical properties. Various chemical analysis techniques, such as X-ray fluorescence (XRF), atomic absorption spectroscopy (AAS), and infrared spectroscopy (IR), are employed to determine the elemental composition and structural characteristics of minerals. These techniques provide accurate and reliable data for quality assessment and process optimization.

Testing Standards and Regulations

To ensure the safety and reliability of mineral-based products, testing standards and regulations are in place. These standards outline the acceptable limits of impurities, physical properties, and chemical composition for different industrial applications. Compliance with these standards guarantees that minerals meet the required quality criteria, minimizing potential risks and ensuring consistent product performance.

In conclusion, understanding the composition and chemical properties of minerals is crucial for their successful utilization in various industrial applications. From building materials to energy production, metallurgical processes, chemical manufacturing, and the pharmaceutical industry, minerals play a vital role. Their reactivity, solubility, and acidity/alkalinity determine their effectiveness in specific processes, while proper quality control and testing uphold product quality and safety standards. By harnessing the significance of mineral chemical properties, industries can optimize their operations and develop innovative solutions for a wide range of practical needs.